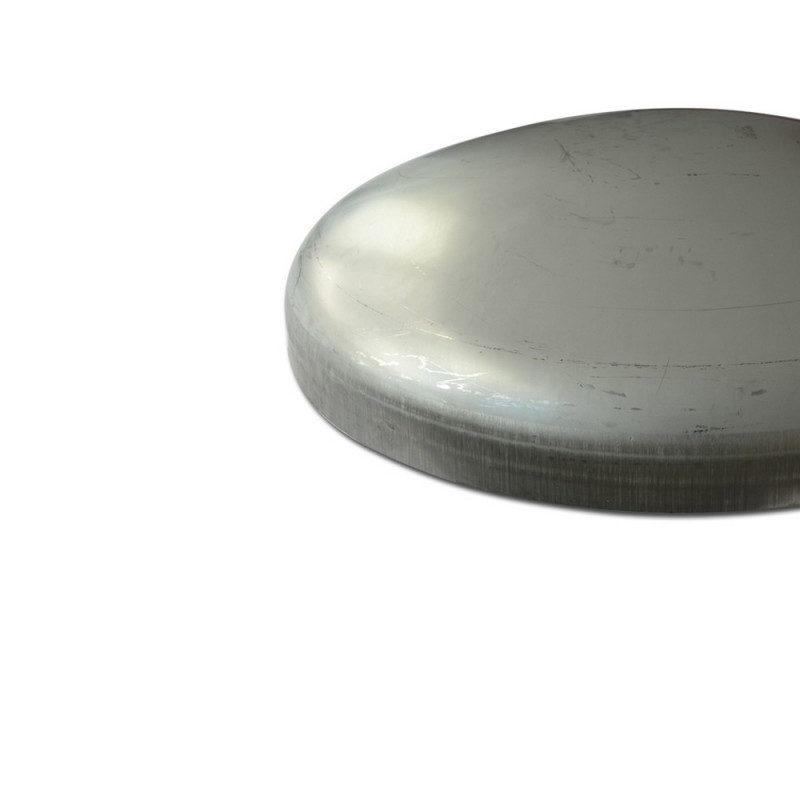

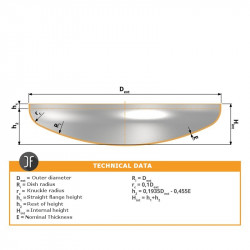

Klopper head with a diameter of 1000 mm, with a 8 mm nominal thickness, in 304L stainless steel, which complies with DIN28011 standard.

This head is ideal for stainless steel pressure vessel manufacturing.

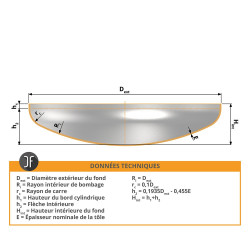

Info: dimensions are in millimeters.

Payment secured

Fast delivery

decreasing prices

You might also like

Customers who bought this product also bought:

Dished heads are manufactured by cold processes, spinning or press-forming.

All our dished stainless steel are supplied without grease. No heat treatment is performed after forming.

This 304L stainless steel end is manufactured in accordance with DIN28011.

The dish radius is 1000mm.

The knuckle radius is 100mm.

The straight flange height is 50mm.

Moreover, Distrifond is able to provide you material certificate 3.1 according to EN 10204 with EN 10-0287 and ASTM A240 for each of your dished ends.

Thanks to the direct relationship with our manufacturing partners, we want to guarantee a short circuit without any intermediary. This allows the control of raw materials but also ensures a high level of quality at an affordable price. For our customers, this guarantees the quality of our dished ends which is perfect in case of urgent deadline.

These bottoms are manufactured in accordance with DIN28011. Manufacturing tolerances strictly follow the DIN28011, highlighting the tolerances on its height, its thickness after forming.

For a tank bottom ordered at a nominal thickness (also called starting thickness) E, the actual thickness measured after forming may differ from E, not only because of the tolerances on the thickness of the sheet, but also because of changes caused by the forming process.

Data sheet